Making portland cement (the most common type of cement around the world) releases significant greenhouse gas emissions, but low-carbon production methods have been developed and are ready for market expansion. Funding from the massive new climate law could be the key to accelerating their commercialization.

Mitigating CO2 emissions from cement production is critical because production is expected to substantially increase in the coming years and decades to meet rising construction and concrete demands worldwide, and emissions are expected to increase accordingly. With the global population, economic development, and urbanization all projected to increase dramatically over the next 40 years, global building floor area is expected to double by 2060 with the addition of 2.4 trillion ft2 (230 billion m2) of new floor area to the global building stock. This growth will be equivalent to adding an entire New York City to the world every month for 40 years. Additionally, in the U.S., funding from the recent infrastructure law further encourages investments in the construction of roads, bridges, and water systems, which will increase the use of cement and concrete. While production of both has become more efficient in recent decades, a dramatic change in the requisite heating and fueling technologies is essential if we want to decarbonize the process and industry more fully.

An impressive $5.8 billion in the climate law (the Inflation Reduction Act of 2022) is dedicated to tackling problems like these. Companies looking to implement new technologies to reduce greenhouse gas emissions in the industrial sector can soon apply to receive funding through the Advanced Industrial Facilities Deployment Program (AIFDP) to cover part of the cost of deploying these technologies. ACEEE partnered with a coalition of NGOs in urging the Department of Energy—charged with disbursing the funds—to invest in truly transformational decarbonization technologies.

The law references numerous potential areas for technology funding, from steel and chemicals to cement. Each is important, and there’s no one silver bullet. In this post, we show why emerging low-carbon process-heat technologies for cement production may be a particularly effective use of these funds in decarbonizing the cement industry.

Why cement?

Cement is a key ingredient in concrete, a widely used building material. Producing that cement is a carbon-intensive process and is responsible for the bulk of the CO2 emissions associated with concrete. About 60% of the emissions are released during the breakdown of limestone (known as calcination), and about 40% are emitted in burning fuel to heat the kiln (known as combustion). The industry has worked to reduce its carbon intensity through energy and material efficiency over the past four decades. Yet significant reduction opportunities remain to decarbonize process heat and should be a particular focus of the AIFDP technology portfolio.

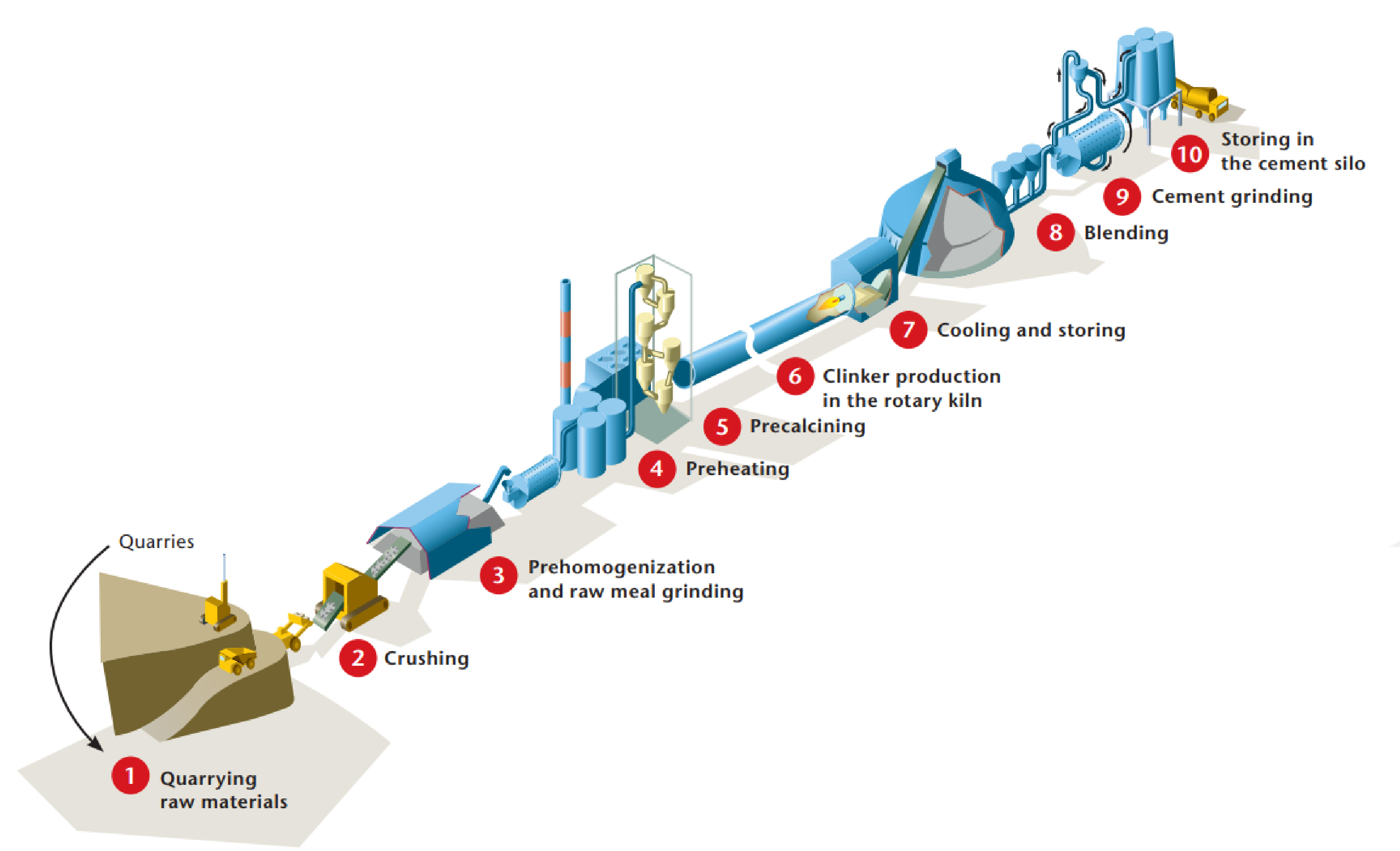

Cement manufacturing process (Source: IEA and WBCSD, 2009)

There are two critical process stages to target for emissions reduction: (1) the precalciner (600–700°C) and the rotary kiln (1200–1500°C) used to create clinker. The majority of CO2 emissions arise from the precalciner, where the CO2 is generated in the breakdown of limestone and where 60% of the fuel is fired. Calciner CO2 reduction tends to be easier—compared to the rotary kiln—given the relatively lower (600–700°C) temperatures that must be achieved. Kiln technologies are a particular challenge because of the high process heat temperatures (up to 1500°C) that must be reached for the limestone calcination process to produce clinker.

Options for decarbonization

Transformative technologies for industrial decarbonization and emissions reduction may broadly be categorized into process (e.g., heat) and product (e.g., alternative chemistries) options. On a systems level it’s useful to recognize that deployment of technologies in either category will influence and create additional opportunities for optimization in the other. Here we focus on transformative process heat technologies, many of which potentially impact the overall process (not just one stage) and allow improved application of energy efficiency measures—such as waste heat recovery and process optimization—afforded by smart manufacturing. This consideration was also articulated in the DOE Industrial Decarbonization Roadmap.

In looking at potential synergies between product and process levels, it is useful to note that there are transformative technologies that increase material efficiency, such as the addition of supplementary cementitious materials (SCMs), like calcined clays, to produce low-carbon blended cement products. These cements require much lower temperature ranges (700–850°C) compared to traditional portland cement (1500°C). These lower heat requirements, in turn, may then open up process heat technology options in lower temperature ranges as well. Conversely, as these lower-process-temperature technologies are implemented, the industry may be able to accelerate its transition to manufacturing lower-carbon cements like calcined clay cements, thus reducing overall emissions faster and in greater quantities. Calcined clays are currently being piloted by cement companies in some U.S. states.

To decarbonize portland cement production (which represents the higher emissions process in widespread use) in a truly transformative way, we have two key opportunity pathways: (1) electrification, and (2) the use of low carbon thermal resources to reduce or eliminate fossil fuel combustion. Technologies exist that are in the market commercialization phase (also known as the 2nd valley of death), with some targeting either a specific stage of the manufacturing process or others potentially impacting the entire process. Below we discuss some candidate transformative technologies currently in prototype, pilot, or limited-use stages in Europe, where governments have invested in their commercialization over the last 20 years. Many may be appropriate for support and funding to commercialize and scale up their use across the U.S. cement industry. In fact, almost all these options are being tested somewhere in the world and are being considered by the cement industry for pilots and broader implementation.

Electrification pathway

Indirect calcination using electric kilns with indirect electrified heating (in the preheater) is relatively easy to design and incorporate in new cement plants. Existing precalciner kiln systems may be retrofitted with electric kilns (with some loss of thermal efficiency). This pathway to decarbonization is dependent on significant growth in the availability of low and carbon-free electricity.

One electric process heat approach is based on a concentrating solar thermal (CST) technology, which uses solar energy in place of fossil fuels to reach high temperatures in cement processing. The technology is currently being piloted in partnership with a cement company and is expected to reduce or eliminate most of the carbon by using solar energy to drive the manufacturing process. CO2 emissions from the breakdown of limestone would be captured in a heat transfer fluid and potentially be converted into synthetic fuels, also using solar fuel technology, for further use in other products. Additionally, this technology may be paired up with a thermal storage system for uninterrupted operation round the clock. This technology is a next generation version of the sunshine-to-petrol technology developed by DOE’s Sandia National Laboratories.

The use of electric heating for indirect calcination may also be combined with carbon capture and beneficial use, given the pure concentrated stream of CO2 typically produced. The CO2 can then be used to create other manufactured products in a circular economy approach—making a range of products from chemical precursors to more unique products like carbon nanotubes and bioplastics. An option offering indirect heat and known as direct separation calciner technology efficiently separates CO2. The modular design can be retrofitted and scaled to capture up to 100% of process emissions from a cement plant and works with a variety of energy sources, including electricity and alternative fuels. This technology is currently being piloted through LEILAC (Low Emissions Intensity Lime and Cement), an EU Horizon 2020 research and innovation project with multiple cement manufacturers at multiple plants.

A more technically challenging option is to electrify the kiln. In Scandinavia, one fully electrically heated rotary kiln has been developed and is currently being tested in pilot projects through a consortium of 11 business entities. The prototype makes it possible to run a cement plant with near-zero CO2 emissions. The breakdown of limestone with the release of a higher-concentration CO2, undiluted with flue gases, offers opportunities for carbon capture and beneficial use in manufacturing other low-emission products.

Low-carbon thermal resource pathway

Options in this pathway include the use of biofuels, plasma energy, or hydrogen technology in cement kilns. Waste-derived fuels from biomass sources (e.g., paper, processed sewage pellets, meat, and bone meal) carry a zero-carbon factor and are considered 100% renewable. As the percentage of non-biomass sources in the fuel mix increase, so does the carbon emissions factor. Hydrogen: Theoretically, this option offers an unlimited supply of fuel using renewable energy, such as solar and wind, but it would require equipment modifications and cost more than natural gas (at current prices). Some no-combustion heat source technologies for kilns are being piloted in the United Kingdom and Europe.

In the UK, pilots at cement plants are using hydrogen, biofuel, or plasma energy. For example, one pilot relies on grey hydrogen (which can be substituted with green hydrogen in the future) in a 100% net zero fuel mix. In Sweden, a cement company and a utility are jointly conducting a pilot of plasma energy in cement kilns. The initial evaluation found that using electricity to supply heat during the clinker production process was feasible using plasma technology (based on low-carbon ionized gas) and competitive compared to other options for achieving high reductions in carbon emissions. It found that future electrification of the cement plant would integrate well with planned expansions to onsite wind power generation.

Thermal storage can be integrated with renewable sources that are cost-competitive with hydrogen options, with initial piloting getting underway in 2022. A technology developed in Finland known as a RotoDynamic Heater (RDH) offers a process heat electrification and storage option for precalciners. The technology is set to be piloted in commercial demonstration projects in partnership with a cement company, can be retrofitted in existing plants, and is expected to be ready for large-scale use by 2024.

Another technology developed in the U.S., known as a heat battery, is a drop-in, zero-carbon replacement for industrial boilers and furnaces. The heat battery charges with intermittent electricity from local wind and solar or from the grid. Electricity powers radiant heaters with zero loss. The system delivers continuous superheated air for use as process heat or electric power, with over 98% efficiency. This technology converts intermittent power to a source of continuous heat, which is valuable in industrial applications that require continuous production—like the cement industry.

Co-benefits of using AIFDP funds to support transformative kiln technologies

Many of the transformative technologies currently in prototype or pilot testing stages would benefit from the construction or installation of commercial-scale projects in the U.S. (the First to Third projects of a new technology) and lead to widespread replication of the technology with substantial emissions and pollution reductions from eliminating fossil fuel combustion. These reductions will directly benefit communities surrounding the plants by reducing harmful health exposures. Additionally, with the scale-up of such technologies comes the much-needed re-skilling and development of a trained and available workforce, ideally from surrounding communities. Producing low-carbon cement and concrete would also serve to work synergistically and further amplify federal green procurement initiatives that create demand for such products. These shifts could create a cascading effect to support market transformation.

Cement kiln electrification and non-combustion heat-sourced technologies represent an important opportunity for AIFDP support that would accelerate key activities already in progress in the cement sector. The industry is highly motivated to address its carbon emissions on all fronts, even the historically challenging ones. These projects would enable greater decarbonization to meet climate goals and counteract any expected additional emission increases by mid-century. ACEEE is engaged in ongoing research in this area and will publish more detailed technical information in the new year.