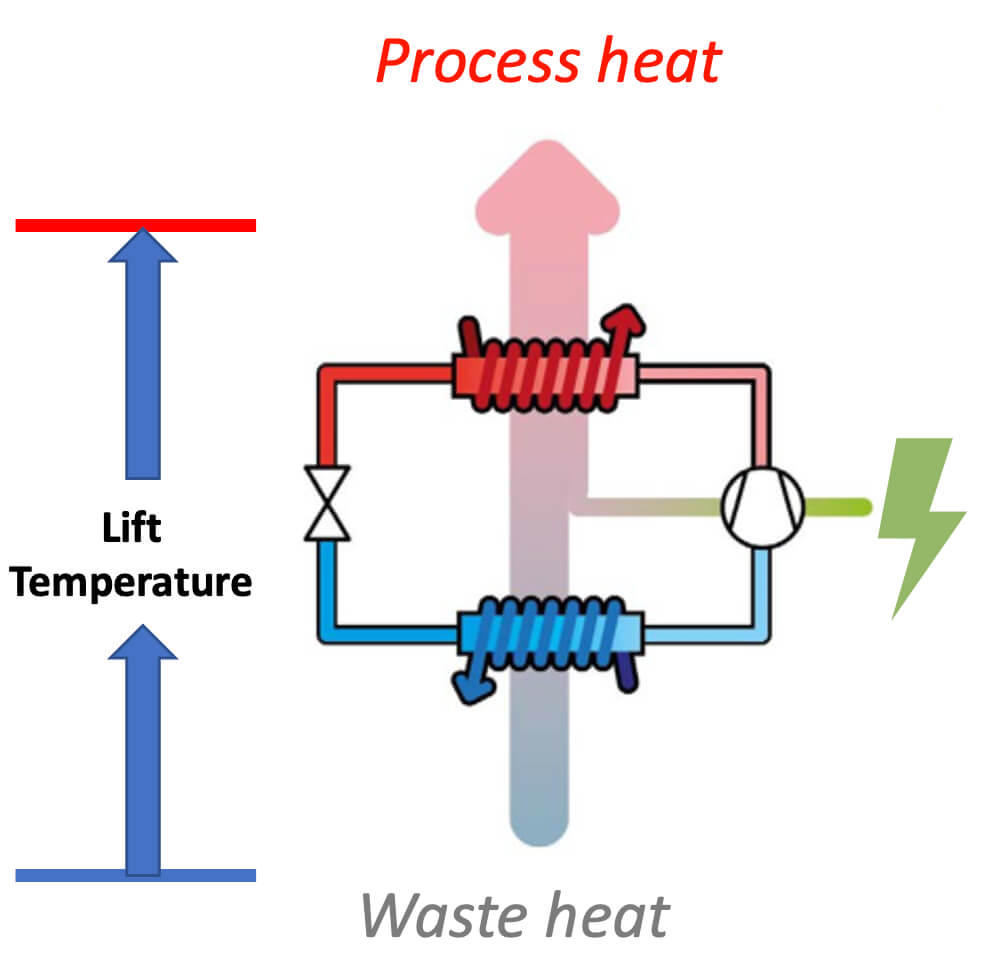

Heat pumps are making headlines these days as a solution that can reduce carbon emissions while delivering the heat necessary to keep buildings warm and manufacturing running. Heat pumps are a key focus of the Department of Energy’s Industrial Heat Shot, which aims to develop industrial heat decarbonization technologies with a minimum of 85% lower emissions by 2035. Heat pumps are also one of the five clean technologies that President Biden selected to prioritize when he invoked the Defense Production Act in 2022. While heat pump technologies for buildings have received substantial attention, the potential of industrial heat pumps (IHPs) to electrify industrial process heat is currently underappreciated. The production and use of process heat accounts for as much as 51% of on-site industrial energy use. Today, electricity supplies less than 5% of that energy demand, while carbon-intensive fossil fuels such as natural gas makes up the rest.

Several types of commercially available electrically powered IHPs can provide process heat up to 160°C (320°F) to replace much of the fossil fuels used in thousands of industrial operations, dramatically reducing emissions. More advanced heat pumps that can supply heat up to 280°C (536°F) are currently in development. IHPs can provide much of the process heat needed in major energy-consuming industries, including food and beverage manufacturing, pulp and paper, and chemicals. ACEEE research shows that IHPs can cut the energy use associated with industrial process heat by up to one-third and enable CO2 savings of between 30-43 million tons per year—equivalent to the emissions from 6.5–9.2 million gasoline-powered passenger vehicles driven for one year. IHPs can also be economical, offering paybacks of under two years in some applications. IHPs are not a new technology. They were developed and commercialized for industrial use in the 1980s but stalled in North America because of cheap natural gas. Today, the combination of the urgency of the climate crisis and advancements in the capabilities of heat pumps makes them a prime solution for reducing industrial emissions.

In order to expand the proliferation of IHPs in industrial applications to meet this significant decarbonization potential, it is essential that policy enablers are created at the federal and state levels to mitigate economic, market, and regulatory barriers. The United States must minimize the perceived risk of switching to IHPs through economic incentives, develop a workforce capable of supporting IHPs in the field, and create a domestic IHP market by removing regulatory hurdles and encouraging global suppliers to expand into the United States. Pilot and demonstration projects are also needed to prove the viability of IHPs. We must pair these actions with further electric grid decarbonization and expansion to maximize GHG emissions reductions as industry goes electric.

For several years ACEEE has been working to accelerate market transformation toward IHPs. Our prior work includes a research report on the decarbonization opportunities and economics of IHPs in select industrial processes, training sessions with partner electric utilities on potential IHP pilot projects with industrial end-users, the creation of a fact sheet and scoping questions for industrial partners that may be interested in using IHPs in their facilities, and blog posts on the potential to electrify process heat. Our future work in the heat pump space will build on these efforts toward large-scale support for implementation and evaluation of IHPs across the country as we look to engage with manufacturers, policymakers, energy efficiency programs, and industrial companies to pursue the most promising pathways toward industrial decarbonization.

IHP Workshops

at 2023 Energy Efficiency as a ResourceIHP Workshops

at 2023 ACEEE Industrial Summer Study-

Welcome and Introduction

Agenda (Dan Brown – Cascade Energy)

ACEEE ongoing work on IHP market transformation (Andrew Hoffmeister, Neal Elliott, Paul Scheihing – ACEEE)

-

Global IHP Experience

IHP technology readiness, economic conditions and sustainable refrigerants (Cordin Arpagaus – Eastern Switzerland University of Applied Sciences)

EU High Temperature Heat Pump (HTHP) demonstrations (Veronika Wilk – Austrian Institute of Technology)

IEA Annex 58, HTHP applications (Benjamin Zühlsdorf – Danish Technological Institute)

Policy learnings from Denmark on IHP support, REPowerEU Initiative (Fabian Bühler – Danish Energy Agency)

-

Supply Chain Efforts (Initiative Partners)

Renewable Thermal Collaborative (RTC) and IHP user perspectives (Blaine Collison – David Gardiner & Associates)

National Electrical Manufacturers Association (NEMA), and IHP manufacturer perspectives (Steve Griffith – NEMA)

-

Utility Perspectives

Electric Power Research Institute perspective: challenges, district heating, drying applications (Ammi Amarnath – EPRI)

Utility perspective: ongoing work, learnings from customers (Chase Cortner – Southern Company)

- Policy Support and Federal Investment

-

Energy Engineering perspectives

Need for implementers, engineering, regionality, early pathways (Steve Koski– Cascade Energy)

Resources

GET INVOLVED

Interested in participating or learning more? Please email:

Andrew Hoffmeister